Putting power to the ground is a quest that takes into account many factors – one must address concerns of weight distribution, parts integrity, tire choice, and more, to reach a logical conclusion. One aspect that can lead people astray is the issue of picking the right axle, and whether or not it’s best to swap out rearends or pick up something straight out of the junkyard.

If you’re just starting on a project car or are in the middle of building one, we’re sure you’ve been trawling the forums looking for answers, wandering through junkyards scouring piles of rusty parts, or heading to swap meets with your fingers crossed.

If you’re just starting on a project car or are in the middle of building one, we’re sure you’ve been trawling the forums looking for answers, wandering through junkyards scouring piles of rusty parts, or heading to swap meets with your fingers crossed.

That’s why we came up with this spotlight article. Read on, as we get the advice and wisdom from one of the foremost experts in the field of axles and rearends, Moser Engineering. We asked the company’s Jeff Anderson to help us understand why and how axles from the aftermarket improve upon what went into the original, stock versions.

The Moser Way

Moser Engineering traces its origins back to Greg Moser. He was passionately involved in drag racing and the building of performance vehicles, having raced motorcycles, Camaros, Corvettes, and other asphalt terrors. Craving competition, however, made him hate waiting around for certain parts.

“When he was racing, he soon realized that he couldn’t wait four to eight weeks for axles, not if he wanted to stay in the points chase,” said Anderson. “He realized that he needed to do something about it, so he started researching ways to respline stock axles so he could keep racing. His buddies began to rely on him when they had failures and needed to make it to the next event the following weekend.”

Together with his son Rob, the Mosers picked the local scrapyards clean of parts, and soon found themselves with no remaining supply. The only choice that remained, was for them to start forging axle shafts themselves. Since they were going to build new axles, they also decided they should build parts that would last longer than what was currently available. To accomplish this would require not only supplies, but expertise and experience as well.

It is not uncommon to see 250 pairs of axles and 20 rearend assemblies shipping out every day. Each one is custom-made to exact specifications from scratch, and the majority of our custom parts ship in two business days. — Jeff Anderson, Moser Engineering

“Greg’s background was in running a large, forging company,” said Anderson. “The vast majority of his knowledge came from supplying heavy-duty forgings for the largest earth-moving company in the world, along with aviation and military customers. He had a group of experts working with him that possessed engineering degrees, doctorates, and experience in related fields and manufacturing processes.”

“This was a group of employees and friends that wanted to help him with their experience and expertise in metallurgy. They supplied a knowledge base to Greg that wasn’t readily available to anyone else in our industry. With this knowledge and connections, Moser managed to figure out a manufacturing process, and then designed machines to reach a goal that was deemed impossible by others at the time. He wanted to make a custom, made-to-order axle to an exact length, and do it in the shortest amount of time possible.”

A determination of such magnitude, combined with Moser’s innate business savvy, allowed the company to grow from a small business working in a personal garage with two employees, to a facility measuring 100,000 square feet, and employing nearly 70 people. “Greg was a driven individual, and is also competitive to his core,” affirmed Anderson. This drive has been passed on to his son Rob and grandson Justen, both of whom are ensuring the company retains the determination and legacy of the founder.

Manufacturing And Testing At Moser Engineering

Much of what allowed Moser Engineering to succeed early on has been carried through to present day, starting with the metal. The company only uses USA-made steel, as well as alloys that are sourced and purchased locally.

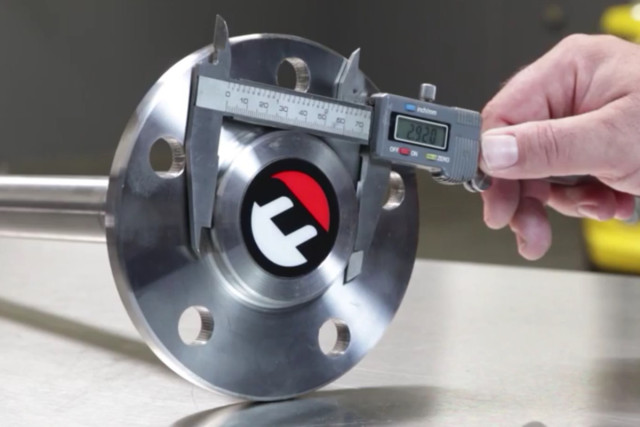

“The castings we use for our 12-bolt and 9-inch cases, along with performance covers used on the 12-bolts, are made here in the states,” said Anderson. ” Our axles are forged in Portland, Indiana, using Moser-owned tooling and dies. The forgings come in to our campus where every step of the process from rough turning to final turning and ultimately machining, which includes the splining processes along with induction heat treating is controlled by us.”

Testing on Moser’s axles is done partially in-house, and just to be extra-careful, products are sent out to independent labs to verify the findings of Moser’s staff. “We utilize one of the largest accredited labs that services not only the forging and automotive industries, but the aerospace and defense industries as well,” said Anderson.

The Good/Better/Best For Chevy Cars

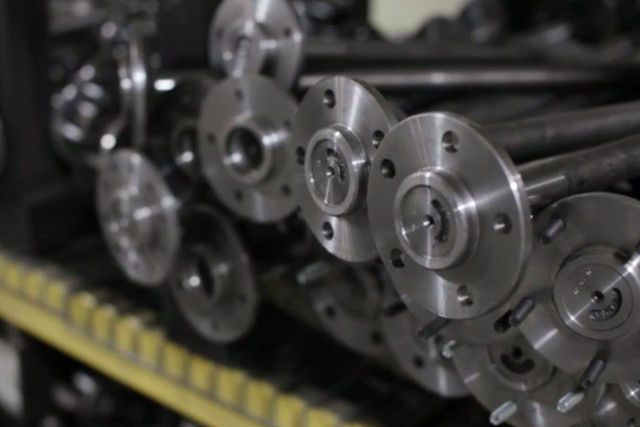

When C-clip axles can’t cut the mustard, Moser uses a press-on style bearing that not only retain the axle in case of failure, but also meets the safety requirements of almost every professional racing series today. Pictured above are Moser custom-alloy axles.

There are two predominant types of axles from Moser that are relevant to Chevrolet applications: those for street use, and those designed for performance. The Street versions are made from Moser’s street-and-strip alloy, and use an induction-heating process that delivers a 25 percent increase in strength, while retaining the original dimensions for retaining a factory-style C-clip axle. However, an axle that is retained by a C-clip, really isn’t sufficient when it comes to more performance-oriented uses.

“To improve on the C-clip retaining configuration, we have to do away with the C-clip groove, in favor of a safer and more secure retaining device,” explained Anderson. “Our performance-style axle incorporates a press-on style bearing that is not only better at retaining the axle in case of failure, but also meets the safety requirements for almost every professional racing series in the world today.” Anderson admits that stronger axle combinations can be made, but they require moving away from classic Chevrolet housings, and utilizing a full-floater housing (like the Ford 9-inch rearend) to accommodate applications meant for hardcore drag racing, stock car, or road course racing.

Differences Between Hollow And Solid Axles

The collective mind of gearheads’ knowledge and experience has invented some incredible ways to save weight in race cars. From gutted interiors to the use of carbon fiber, the ideas and methods invented in the past century have had a profound effect in the pursuit of speed.

As it pertains to axles, Anderson said, “There are ways to save weight when things get really competitive. You can lighten parts to reduce rotational mass, and one way of doing this with axles is to lighten the axle flange and rifle-drill axle shaft itself.”

Rifling – the practice of applying helical grooves to a piece of metal – applies best to track cars that don’t see street use. Drilled axles are not recommended for use on public highways, because the random and crummy ways normal asphalt is maintained can shock a lightweight, rifled axle, and cause it to fracture. “If If the car is for dedicated track use, then the weight savings can be substantial, depending on the length of the shaft,” said Anderson. “This can help you to remain competitive and reduce the load on your engine and drivetrain, giving you better performance.“

Spline Count And Its Effect On Axle Performance

The old saying of “the more, the merrier” works in a lot of situations: money, friends, pizza, beer, horsepower, and so on. But what about splines? Anderson broke it down in a way that is simple to understand.

“Think of it this way – the more splines an axle has, the larger the diameter axle shaft. With everything being equal, this means more strength and torque-load capability. In essence, more power can reliably and safely make it to the ground. There are however, limits to the size of axle shaft that will work with certain rearend assemblies.”

Anderson recommends contacting Moser Engineering for further questions on this topic: “If you have any questions on what is available for your application, just call us. We are more than willing to answer your questions.”

High-Tech Designs, Real-World Results

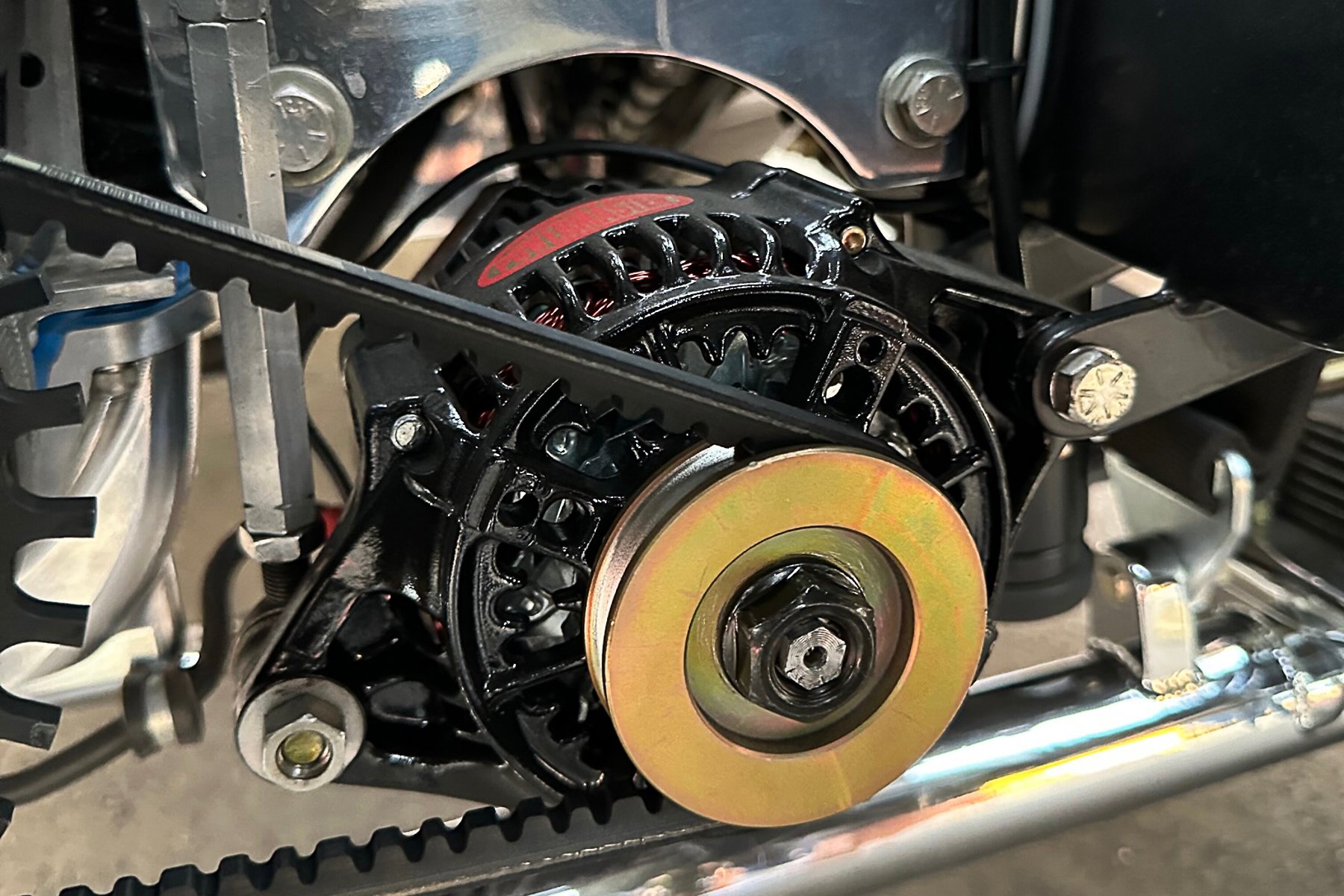

Everyone at Moser is proud of the fact that its products can be attributed to successful usage in not only street applications, but racing applications as well. Products from Moser Engineering have found their way into top-tier racing classes like Pro Mod and Pro Stock, but it’s the folks in Sportsman and Index class racing that speak to the Moser method and legacy. That is because those same people who spend sleepless nights working on their cars are what made the company what it is today.

“We have always focused on the little guys, and tried to shine a spotlight on them, because for every high-end build or pro-style floater rearend we build, we have 1,000 sportsman racers or street rod guys building cars using our products,” commented Anderson. “We supply the strongest axles with the fastest turnaround in the industry. The founding principle that Greg demanded of his company still drives us today. It is not uncommon to see 250 pairs of axles and 20 rearend assemblies alone shipping out every day, and that doesn’t include all the other Moser parts. Each one is custom-made to exact specifications from scratch, and the majority of our custom parts ship in two business days.”

“So when a deadline is looming and you have a guy who stays up all night so he can drive to the next show or race, that guy is the guy I want to say I am proud of for using our products, and trusting us to get it to him on time. And let’s face it – when that person is counting on you to deliver so he can attend an event that he has planned on for months or years, it doesn’t matter what you say your past successes are, if you can’t deliver with the same expectations to every single customer.”

Moser Engineering may have started small, but its growth has not inflated its sense of importance. With people like Anderson, and Rob and Justen Moser, working around the clock to improve processes and enhance customer satisfaction, the company has a healthy outlook and a clear trajectory. Find out more about Moser by visiting its website, or give them a call using the provided contact information below.