If you’re a late-model Corvette owner and you’ve ever been in the market for a new clutch, then you’ve discovered that there is such an array of options to choose from, you could find yourself being a little bit lost and confused. To make things even more difficult, thanks to the transaxle layout of the C5 and C6, swapping a clutch is a far more involved process than on a car with a more conventional driveline. A clutch swap isn’t the kind of job you want to do twice on these Corvettes, so getting it right the first time (and having the room to grow for more horsepower and torque down the line) is critical.

Though we’ve done a swap or two in our time, when it comes to serious matters like this, we always turn to the experts. Helping us explain to you the differences with each application are representatives from ACT, McLeod, SPEC, and Centerforce – each providing insight with their options for the Corvette enthusiast like yourself. We cut through the fluff and confusion, by bringing you this no-nonsense article on picking the clutch that’s right for you and your application.

While we’re at it, we’ll be selecting a clutch kit from one of these three manufacturers for our own 2000 Corvette project car, Y2K. So read along and let this guide help you select the right clutch for your 1997-2013 Corvette!

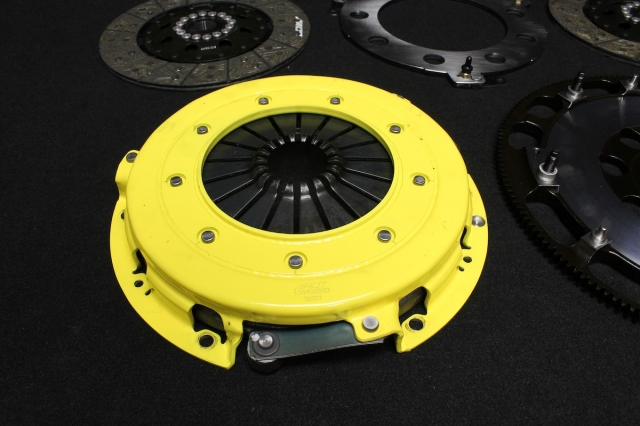

Advanced Clutch Technology

One of the things that stands out when you start digging into ACT‘s line of clutches is their emphasis on selecting the right individual components for each application, whether that’s street, strip, road course, or what have you. ACT’s Chris Bernal helped walk us through all the different considerations, starting with one of the most important aspects – the friction material used.

“The study of friction materials has a long and interesting history, and newer developments are constantly being tested,” Bernal explains. “The organic materials of the past were often based on asbestos, which has been replaced by sophisticated blends of fibers, metals and binders. These offer the most comfort on the street, with some providing extended temperature ranges and good recovery properties.”

“The study of friction materials has a long and interesting history, and newer developments are constantly being tested,” Bernal explains. “The organic materials of the past were often based on asbestos, which has been replaced by sophisticated blends of fibers, metals and binders. These offer the most comfort on the street, with some providing extended temperature ranges and good recovery properties.”

Of course, comfort is not always the leading factor in decision-making for enthusiasts, so Bernal advises, “For more aggressive use (racing, drifting, etc.), there are many sintered materials to choose from. These range from less friction than organic to almost twice as much. The higher friction levels tend to come with rather sudden engagement characteristics, which makes them far less suitable for the street. It is always best to use clutch discs with the same friction material on both sides, so that the thermal properties and coefficients of expansion are identical, reducing the chance of disc distortion at higher temperatures.”

To Puck or Not to Puck

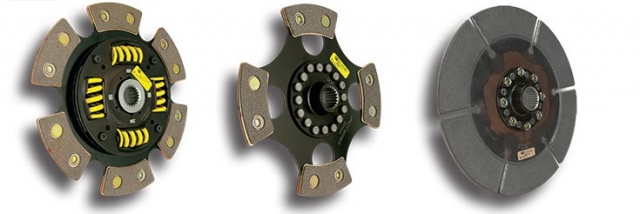

Another important consideration is the physical layout of the clutch disc or discs, which includes factors like whether the hub is sprung or unsprung, and if the disc is actually a disc at all, or a “puck” style piece. “Full-face discs offer the least temperature rise, most engagement comfort, and longest wear,” says Bernal. “Puck-style or segmented discs will grab more suddenly and usually allow quicker shifts, yet will wear out sooner, depending on the material being used.”

Though the difference between a sprung and unsprung hub design is obvious at a glance, similar-looking friction materials can have greatly different characteristics.

Though it might seem counter-intuitive, going with a puck style disc doesn’t have an effect on how much power a particular clutch can deal with. Per Bernal, “There is no difference in how much torque capacity each can handle, aside from their various friction properties, as this is a function of clamp load and friction ring diameters, not segment configuration.”

“Sprung hubs were originally developed to reduce gear rattle noises in the transmission,” Bernal adds. “Many vehicles now come with a dual-mass flywheel, which is often more effective in mitigating, if not completely eliminating, drivetrain noises. Unfortunately, dual-mass flywheels are not service- or modification-friendly and are unsuitable for any type of racing. Most single disc clutch kits are offered with a sprung hub option, which is a big help in reducing gear rattle.”

While it might seem like a puck-style disc would have a lower torque capacity than a full face unit with the same friction material, Bernal tells us that’s not the case.

Are Two Discs Better Than One?

For high horsepower applications, twin disc clutches have become increasingly popular, but where’s the point at which doubling down makes sense? Bernal says, “The crossover point can vary a bit depending on what type of driving is going to be done. Most often, one will do a large power upgrade that might require a very high clamp load (and corresponding high pedal effort) single disc clutch to hold the torque. Moving up to a twin disc clutch can bring the pedal back to a nearly stock feel since there are four friction surfaces available instead of just two.”

Mistakes in clutch selection are often made if you’re only looking at torque output. – Chris Bernal, ACT

Flip the Script

So how do you choose what’s right for you? According to Bernal, buyers should concentrate on how they’re going to use it, rather than obsessing about the power the clutch will hold. “This depends a lot more on driving style and planned use than on power,” he explains. “Performance street driving will have certain requirements, while weekends at the drag strip have others. Mistakes in clutch selection are often made if you’re only looking at torque output. The ACT web site has now has a configurator to help quickly narrow down various available options to the best one. Questions can also be answered on the live web chat. Of course, we have actual humans who answer phones as well…”

McLeod Racing is among the most respected names in the clutch game. We’ve seen their clutches installed in everything from 4th-Gen Camaros to brand new ZR1s, and everything in between.

McLeod is a huge proponent of putting a multi-disc clutch in late model Corvettes. McLeod was actually one of the first manufacturers to develop a “street twin” disc set up when they decided to take the technology that had been so successful on the racetrack and civilize it for use in road-driven cars. Providing insight with this story are McLeod’s Red Roberts and Fred Taylor.

The unique aspects of C5 and C5 clutch selection don’t end with the drivetrain layout. As Taylor tells us, “One of the things you need to keep in mind with late model Corvettes is that they have a limited amount of bearing travel with the slave cylinder. The earlier style clutches that we used with mechanical linkages don’t actually release with that small amount of throw. Most of the mechanical linkages had half an inch of bearing travel, or more.” That means that for a clutch to even work properly, it has to be designed with the short throwout bearing in mind.

“Many of those cars came with an adjustable pressure plate,” Taylor continues. “The actual pressure plate is self-adjusting, kind of like drum brakes. What happens is the fulcrum actually ratchets, and springs help keep the finger height the same, and it never changes on the OEM pressure plates. So it’s really crucial that a replacement pressure plate release very quickly. That being said, the clutches we sell most for these cars are our RST and RXT dual disc clutches, that release with as little as 350 thousandths of bearing travel.”

“The LS1 F-Bodies, the C5 and the C6 all come with the complicated adjustable pressure plates that no one rebuilds and are actually quite expensive to replace. So it just makes sense to upgrade your whole package when you are replacing your clutch.”

Red adds, “The single disc clutch takes a little more stroke because it’s not self-adjusting, and it has to have a little more travel. When these cars first came out we tried messing with the hydraulic throw-out bearing to get the travel right, but that isn’t really where the problem is. The problem was most of the guys who call McLeod looking for an aftermarket clutch have done something to their car to require them to need a stronger clutch – supercharger, nitrous. So that it is what we focus on.”

“If you are going to run a single disc clutch, it can give you fits,” Red says. “We are currently working on developing a pressure plate for a single disc clutch that will have the necessary release without the self-adjusting fulcrum.”

Limited By Physics

Roberts and Taylor point out that there are only three ways to increase clutch torque capacity, and all have inherent compromises:

- “You can increase clamping load, which will translate to more pedal pressure, but that’s not driver friendly because no one likes to drive a stiff clutch; that’s no fun to use in rush-hour traffic, and it’s going to get old real fast.”

- “You can change the disc and use a material with a higher coefficient of friction, so that the lower pressure clamping pressure will still hold well because of the better friction material. The drawback with this is that the clutch will become more like an on/off switch. You go to let the clutch out and the car just wants to churn. Again, this isn’t going to be fun on the freeway at 5:05 PM.”

- “The third way, and our favorite way, is to just increase the clutch’s surface area. The problem with this becomes packaging, because you can only go so big in diameter before you run out of space. Also, the bigger the disc is, the heavier it is when it’s rotating. The further away from center you get, the more rotating rate the disc has and when you disengage the clutch. The disc doesn’t really want to stop spinning. That will cause wear to the syncros because the disc is supposed to slow down when you disengage it from the motor, then the syncros are supposed to help you shift into the next gear when the transmission isn’t spinning so fast. If the disc wants to keep spinning, it’s almost like trying to shift without disengaging the clutch at all.”

The smaller diameter allows us to kill two birds with one stone – Fred Taylor, McLeod

“The smaller diameter allows us to kill two birds with one stone: creating more contact surface with two discs, but yet we are keeping the rotating mass of the clutch in tighter to the input shaft. The rotating rate is not as heavy, and yet you have more contact surface so you can run less pedal pressure. You actually have really soft pedal pressure – our RST clutch feel is very similar to a Toyota.”

“The soft pedal pressure is great for thrust bearings too, because on new cars you have to push the clutch in to start them, and because the motor isn’t turning there isn’t any oil pressure while you are putting pressure on the crankshaft thrust bearing. The higher the pedal pressure, the more wear and tear you will end up putting on the thrust bearing.”

Smooth Operator

Tech Talk: Marcel

“Marcel” is the technical term for a wavy spring sandwiched between layers of a clutch disc. This spring provides a smoother engagement and release by cushioning the clutch assembly. It’s actually named for a 1920’s hairstyle, believe it or not…

“Even the OE’s have gone back to putting in 10-inch twin discs,” Red points out. “Now Ford, GM, and Chrysler are even using smaller twin discs. We’ve even seen that some OE’s that are looking at trying to replace the torque converter in automatic transmissions with computer controlled multi-disc clutches, because you lose a lot of energy through heat in a torque converter when it slips.”

But is a multi-disc clutch overkill for a stock or near-stock Corvette? Not necessarily, says Taylor. “Our base model RST clutch holds up to 800 horsepower. I’ve actually recommended this clutch for stock C5’s just because of the drivability and light pedal effort.”

For those of you unfamiliar with McLeod and their offerings, ‘RST’ means ‘Red’s Street Twin.’ “We developed it back in 2006, and it has become the most popular clutch that we sell today, by far,” Red claims. “It is patented, and will bolt to most OE flywheels. The adapter ring is what’s patented. The beauty of the RST package is that it is a modular clutch assembly. It’s a complete bolted-together package that means you don’t even have to take the flywheel off the car to resurface it. You can just leave it alone. You just take the clutch out of the box, set it on the dowel pins, torque down the six bolts, and it’s already lined up on the spline. All you have to do then in slide the transmission back in, and away you go. There’s no need to align the splines because they’ve already done it for you, and the clutch has its own surface.”

Hints and Tips

- Clutch installation: “One thing I like to do when I’m installing any double disc – right before I tighten down the pressure plate, and I still have the line-up tool through the disc, I like to rotate the tool in either direction, it doesn’t matter which. And what that does is align the leading edges of the splines on each disc, and makes installing the transmission much easier. What happens if you just throw the disc up there is that it is possible to have one disc preloaded one way, and the other disc preloaded the other, and even through you can get the line-up tool in and out, it will make getting the transmission in there very tight.”

- Reusing parts: “Always check your pilot bushings – C6’s have a pilot bearing rather than a bushing. Just get a slide hammer or puller and go to town. Even Harbor Freight sells a nice puller that’s really inexpensive. The replacements are very inexpensive, and just plain cheap insurance against a whole host of problems. You don’t want to skimp on a $10 part, and cost yourself 10 hours trying to R&R the clutch.”

- Diagnosing clutch chatter: “80% of the time the problem is with the clutch, usually the disc. That means that the other 20% of the time the problem is something else: motor mounts, transmission mounts, pilot bushing, misaligned bell housing. So when you have a chatter in your clutch, there are several other things that you need to take a look at besides just the clutch.”

- Flywheel surface finish: “I’ve come across guys who are so proud of their polish job that they’ve done on their flywheel, making it look like chrome. But that will cause chatter, because the flywheel is a seat-in surface and there needs to be plenty of bite to it. You don’t want your flywheel to be perfectly smooth; it needs to have some texture to it for the clutch to properly seat.”

SPEC

When we reached out to SPEC Clutch, David Norton was there to answer our questions. Even though SPEC made their name in the import performance industry, they are there to support those of us with domestic cars too.

He kicked things off by telling us, “There really isn’t very much that is different with the C5 from the LS1 F-Body cars, apart from slight changes to the slave cylinder. LS2 cars with the recessed flywheel don’t really operate differently, but it does call for a different design. The disc is sitting in a recess of the flywheel, and that means the pressure plate’s friction surface has to be below its mounting surface. It will look different because the pressure plate will stick out below the mounting flange on an LS2 unit due to the recessed flywheel. Also, the torque tube is basically an extended input shaft since the transaxle is in the back. All the clutch components are still bolted to the flywheel like a regular car. But the style and design of all clutches for LS1 and LS6 cars is pretty much the same.”

Is it Enough Clutch?

When asked his advice on picking a clutch, he went on to tell us, “The first thing you have to consider is your power goals and how much clutch capacity you’ll need. You have to make sure that whatever clutch you get is going to be able to handle the power that you want it to. If not, you’ll have plenty of issues and definitely some premature wear.”

“Next thing you’ll want to consider is drivability,” Norton continued. “You need to think about how you want the clutch to feel when it engages and how you want the pedal to feel. The nice thing about late model Corvettes is that their hydraulic system really lends itself to drivability, and even with a super-strong clutch you won’t have a rock hard pedal. Ultimately though, it’s the way the clutch feels at engagement that really determines the drivability, especially on the street. On the street you want clutch engagement that is as smooth as possible, meaning you’ll want to always look for a sprung hub disc.”

Norton is also a fan of multi-disc clutches, when appropriate for the application. “Twin disc clutches offer tremendous drivability. The nice thing about double disc clutches is that you can double your capacity over a single disc, but yet have perfect daily drivability. We absolutely suggest that you look at getting more clutch capacity than you need at the time you’re doing a clutch job, so that way you’ll have plenty of room to grow.”

“This is exactly the reason that our twin disc clutches have become as popular as any of our single discs even though they are more expensive. It’s just so much easier to plan your future mods if you have the extra capacity. If you don’t have to upgrade the clutch, you can go ahead and add a supercharger or nitrous and not have to worry about it.”

Not a Fun Job to do Even Once

The clutch install on a C5/C6 can be a bit of a bear if you’ve never done it before. The easiest way is always to just go ahead and drop the whole driveline assembly. Disconnect the bell housing and the torque tube assembly, and move it away from the engine. Then drop the whole rear cross member and transaxle together and leave the rear suspension and brakes in place. Drop the whole thing and slide it out as one completed unit. That is by far the quickest and easiest way to do a clutch job on a C5 or C6. If you start just trying to take out the rear transaxle, and start trying to disassemble the rear subframe assembly, it starts to get a lot more time consuming.

The “easy” way to do a clutch swap on a late model Corvette is to drop the entire driveline and rear suspension.

“We always recommend replacing the slave cylinder since it is inside the bell housing and not that easy to get to,” Norton adds. “Replacing it is pretty much the same process as replacing the clutch, so it’s best to do it while you’re already in there.” Because the incremental cost of replacing parts is so small compared to the labor bill for having to tear it all apart again, it’s worth checking the entire system while the clutch is out.

Per Norton, “When you’re doing a clutch job on a Corvette its very, very important to make sure that your hydraulic system is in good working condition, and that starts with making sure that your slave cylinder is good. Go ahead and put a new slave cylinder in when you’re doing a clutch; they aren’t even all that expensive. And you don’t even need to put an aftermarket slave cylinder in your Corvette. The stock ones are plenty good. We’ve used stock slaves with ungodly pressure plate pressures and have never had any problems.”

Up topside, it’s worth looking at the other major components of the clutch system as well. Norton says, “If there is a weak point in the stock C5 and C6 Corvette’s hydraulic system it’s the master cylinder, and that’s true for most all of the LS powered cars. I think that sometimes people forget about the master cylinder. The seals in the master cylinder take a lot of abuse, especially when you’re speed shifting and hammering hard on the pedal.”

“If you have a an incomplete clutch release problem or trouble getting the car into gear, 9 times out of 10 its caused by a master cylinder that’s not working up to its full potential. You don’t have to replace the master cylinder during every clutch job, but you need to be aware that if you are putting a stronger clutch in the car, your master cylinder need to be in top condition. Otherwise the clutch isn’t going to shift very well and won’t release completely.”

Air in the system is probably the number 1 cause of problems after a clutch install on a Corvette. – David Norton, SPEC

Norton had one final piece of advice on a critical step often overlooked in a Corvette owner’s eagerness to get back on the road – proper break-in. “Seating is most important,” he explains. “Easy stop and go.” For the first 500 or so miles, the clutch needs to be engaged gently, so the surfaces of the flywheel and pressure plate can conform on a microscopic level to the friction discs. Norton concludes by saying, “How you do your break in can change holding capacity. You can lose 80-100 foot-pounds of torque capacity if not broken in properly.”

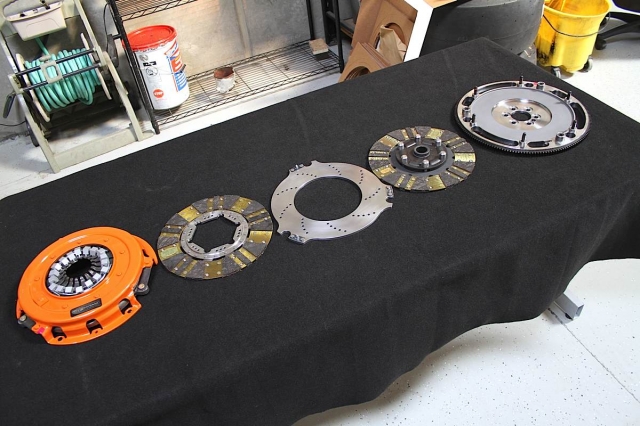

Centerforce

With a high performance heritage stretching back to the 1980’s, Centerforce has always done things a bit differently. Founder Bill Hays’ innovative Centerforce Weighted Clutch System utilizes centrifugal force to improve clamping force without raising pedal effort, as well as making their clutches recognizable at a glance.

Centerforce clutches are hard to mistake for anything else – the ring of weights on the diaphragm fingers are the hallmark of their Centerforce Weighted Clutch System.

We spoke with Centerforce’s Will Baty, and he cut the question of clutch selection right to the chase. “There are three main things you need to consider when selecting a clutch. They are life expectancy, weight, and price.” The life expectancy issue is tied in with torque capacity, and modern clutch designs mean that you can put in a system that has plenty of holding power to spare without killing your left leg or lurching off from every stoplight.

Weight, and more importantly moment of inertia, is a concern – the less power it takes to accelerate the clutch assembly, the more is available to turn the wheels. Equally important is the fact that, as mentioned previously, the less energy stored in the clutch that the syncros have to overcome, the longer the transmission will last between rebuilds. While you might automatically assume that a dual-disc clutch will weigh more than a single, that’s typically not the case. The increased surface area means the two disc clutch can be made smaller in diameter, with a lower moment of inertia than a single with equivalent power.

One Disc or Two?

The third issue, cost, plays a role in the decision as well. In a perfect world, price would be no object, but reality dictates that even for Corvette owners, the bottom line matters. “When picking a clutch, we would always choose a dual disc kit over a single – but that’s just us,” Baty admits. “You get longer life, and more durability. Sure, you’ll pay more and there’s always a market for a single disc for those on a tight budget, or for cars that are stock daily drivers. But for the avid racing enthusiast looking for a long-lasting clutch, with great holding power, we would spend the extra money on the twin disc.”

Of course, if you are making the investment, it’s good to know just what you are paying for, and per Baty, “Centerforce provides you with the equivalent a “cam card” when you buy one of their clutches. It provides you with everything you need to know about your clutch including its specs and limitations.”

Centerforce provides detailed specs with their clutches, including torque graphs.

While this level of detail isn’t going to be fully appreciated by anyone who’s not a clutch engineer, it does give insight into the care that goes into Centerforce’s clutches. Because of the complexity of twin disc clutches, Centerforce balances them as a complete assembly along with the flywheel, while components for single-disc setups are balanced individually.

Multi-disc clutches will always be more expensive than singles due to the higher parts count and complexity, but the advantages of higher torque capacity and longer life make them a good choice for Corvettes. An inexpensive clutch you have to replace again in a year is no bargain…

Inside the Bellhousing

As you can see, choosing the right clutch for your late model Corvette involves a lot of different factors, but thanks to the hard work of our expert panel, we hope you are better equipped to make an informed decision. Replacing the clutch on these cars is a labor-intensive project, so it’s worth spending the time up front to choose the right parts for your particular needs. It’s no longer necessary to trade off torque capacity for street manners, and any of the companies we’ve highlighted here have trained staffers ready to answer your questions and help you make the right choice.